Most hydraulics training has a big problem: you need to be in the right place at the right time with access to the right gear.

If you’re regional, remote, or working in an area without a training facility, your options shrink fast. You either travel for weeks, wait for a trainer to show up, or miss out completely.

That’s a barrier Australia can’t afford right now. Not with the skills gap widening and industries desperate for people who actually know how to diagnose and fix hydraulic systems.

So we built something to fix it.

The Problem With Traditional Hydraulics Training

Here’s the reality: most hydraulics training still requires you to be physically present at a fully equipped workshop.

That works fine if you’re in a capital city or near a major RTO. But if you’re in regional Queensland, remote WA, or anywhere without easy access to training infrastructure, it’s a different story.

You’re looking at:

- Weeks away from work

- Expensive travel and accommodation

- Time away from family

- Limited course availability

- Or no access at all

And even when training does come to regional areas, it’s often watered down or theoretical because the logistics of moving full hydraulic rigs around the country don’t stack up.

The result? Capable people who want to upskill can’t. Employers who need trained technicians can’t find them. And the skills gap keeps growing.

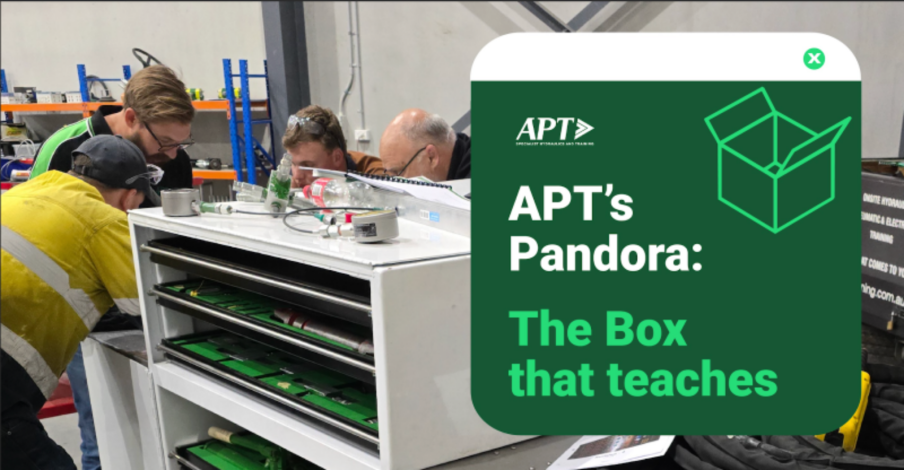

What Pandora Actually Is

Pandora is APT’s portable, remote-enabled hydraulics training system.

It’s not a simulator. It’s not a toy. It’s a real hydraulic circuit with real components, real faults, and real pressures, just compact enough to be shipped anywhere in Australia.

Students work with live valves, pumps, actuators, and circuits. They troubleshoot actual faults. They diagnose pressure drops, flow restrictions, and unstable circuits under load, the same problems they’ll face on site.

The difference? They can do it from regional Queensland, remote NT, or anywhere else without leaving their community.

How It Works for Regional and Remote Learners

Pandora connects remotely, so learners can work through practical assessments and fault-finding exercises without a trainer physically standing over them.

Here’s what that means in practice:

No travel required. The training cube ships to the learner or their local facility. They complete practical work on their own schedule, guided remotely.

Real hands-on work. Every task involves actual hydraulic components. Leak detection. Pressure testing. Circuit troubleshooting. It’s not theory—it’s doing.

Same standard, different location. The quality of training doesn’t drop just because you’re not in a metro workshop. Same faults. Same systems. Same outcomes.

This changes access completely. Someone in Mount Isa can now get the same hands-on hydraulics training as someone in Brisbane, without the $5,000 in travel costs and two weeks off work.

Why We Named It After a Greek Myth

In the Greek myth, Pandora’s box released chaos into the world when opened.

We flipped it.

APT’s Pandora doesn’t release chaos, it contains it. Every fault, every leak, every pressure issue is controlled, safe, and repeatable. Opening the box doesn’t create problems. It teaches you how to solve them.

The myth is about curiosity and consequence. So is troubleshooting. Every time you open a hydraulic system on site, you’re looking for what’s gone wrong and how to fix it—ideally without making it worse.

Pandora gives learners a safe way to build that diagnostic confidence before they’re under pressure in the field with a machine down and a supervisor waiting.

Opening Pandora doesn’t release chaos. It releases understanding.

What This Means for Trainers and Communities

For trainers, Pandora solves the logistics nightmare of delivering quality practical training across regional Australia.

Instead of hauling full-size hydraulic rigs across the country or running watered-down theory-only sessions, trainers can deliver consistent, high-quality practical assessments remotely.

For communities, it means local workforce development without the brain drain. People can upskill without leaving town, which keeps talent in the regions instead of forcing them into cities for training.

For employers, it means access to a bigger pool of trained technicians, especially in areas where hydraulics skills are desperately short.

And from a sustainability angle? Cutting down on flights and long-distance trainer travel adds up fast. Pandora helps reduce emissions while improving access. That’s good for ESG frameworks and even better for getting more people trained faster.

What’s Next: The Full Pandora Series

Pandora is just the start.

We’re building a full suite of training tools named after figures from the same Greek mythology:

Elpis – AI-driven learning support to guide students through complex diagnostics

Prometheus – Advanced diagnostic tools for experienced technicians

Athena – System logic and safety analysis for engineering-level problem solving

Each one expands the platform’s capability and reach, making high-quality technical training more accessible across Australia.

Final Word

Pandora changes how hydraulics training gets delivered in this country.

It breaks down the barriers that keep regional and remote workers locked out of upskilling. It brings real, hands-on learning to people who couldn’t access it before. And it turns every challenge into a safe, repeatable learning opportunity.

If you’re in regional Australia, running a training facility, or managing a team that needs hydraulics skills, Pandora’s built for you.

�� Book a Demo to see how Pandora works. https://apthydraulics.com.au/contact/